Our extrusion blow molding machine mainly produce HDPE and PP hollow products from 5ml to 1000L such as bottles, jerry can, can, tank, jug, jar, kettle, canister, children toy, ocean sea ball, flate bridge, manniquin, traffice barrier, seat, auto part, table plate, pallet etc...

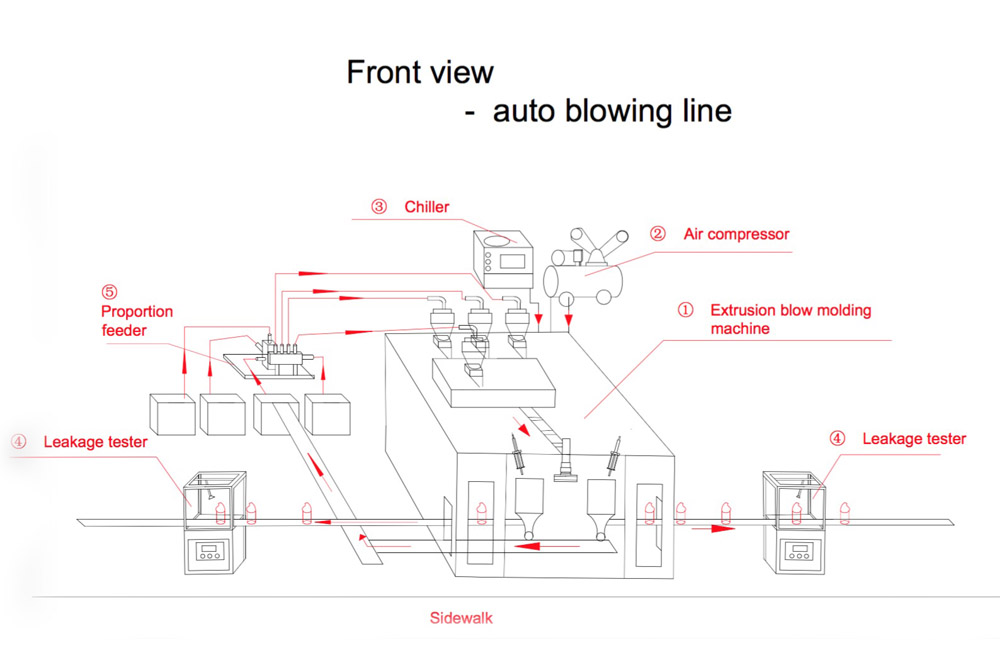

our produce line includes:

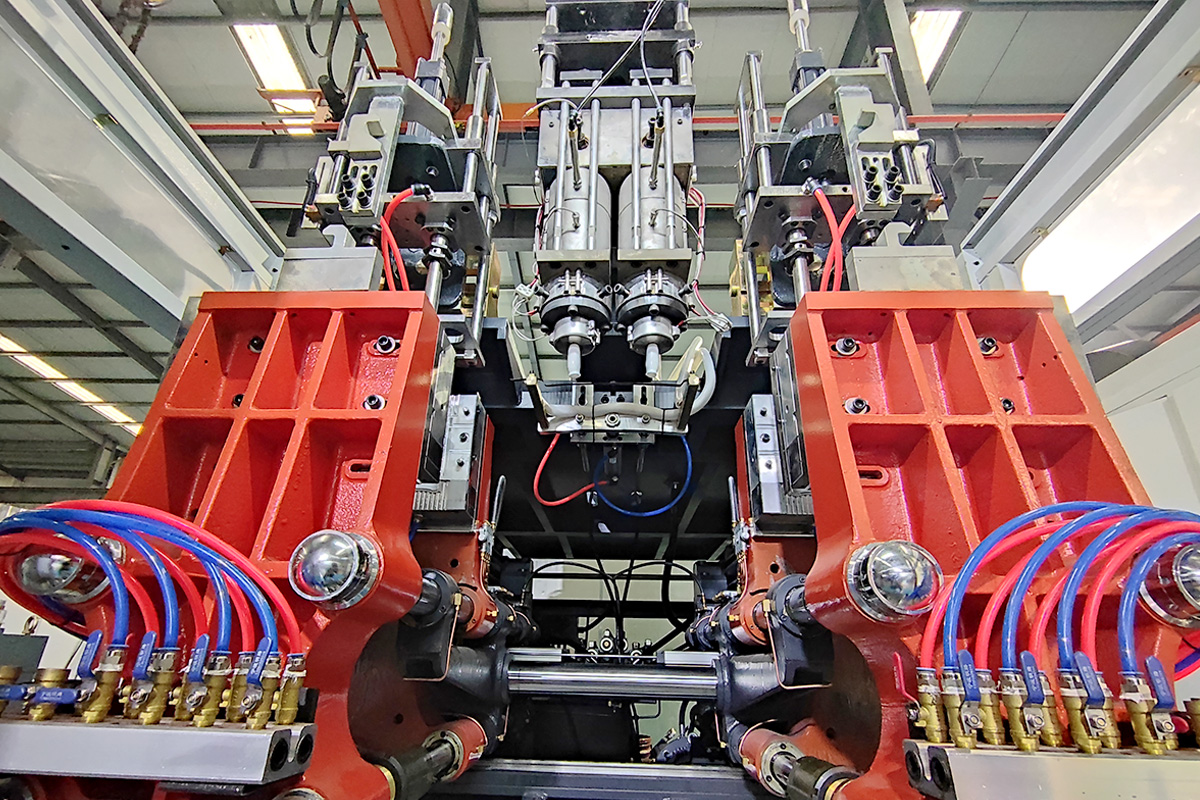

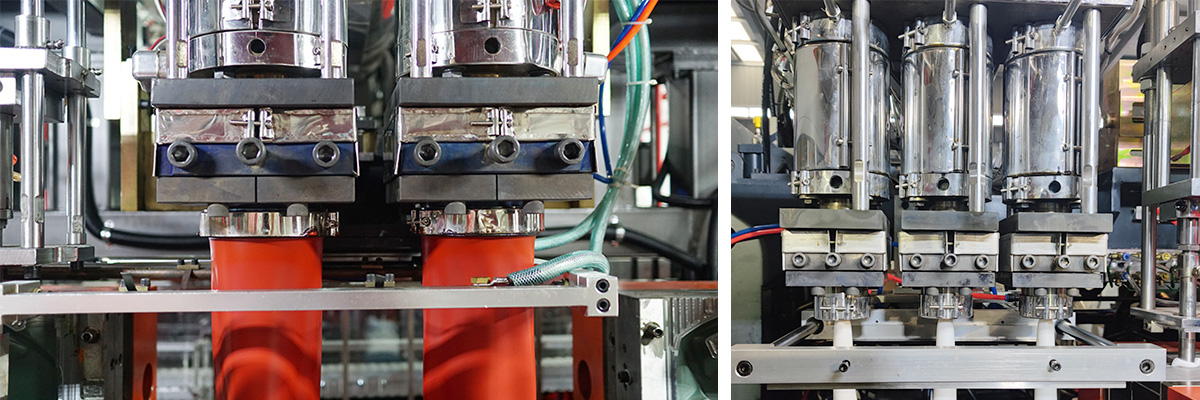

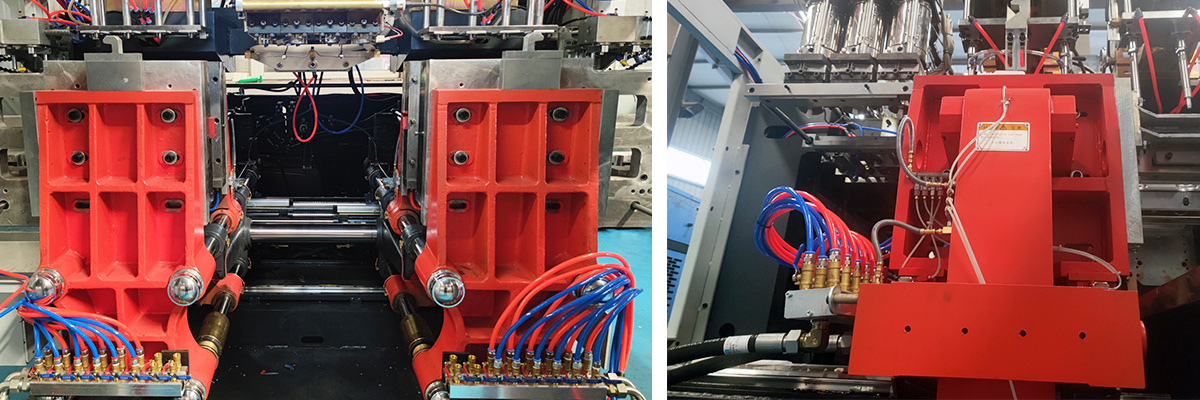

Extrusion blow molding machine

conveyor

leak tester

auto-loader

mixer

chiller

compressor

granulator

others

Welcome to contact us if you are interested.

SPECIFICATIONS | HJS80D |

Material | PE PP PVC PA... |

Max container capacity | 10L |

Number of die | 123,4,6 |

Machine Dimension(LxWxH) | 3.3*5.5*2.8m |

Total weight | 8.2ton |

CLAMPING UNIT |

|

Clamping force | 150kN |

Platen openning stokes | 220-620mm |

Carriage stroke | 540mm |

Max mould size(WxH) | 520*460mm |

EXTRUSION UNIT |

|

Screw diameter | 80mm |

Screw L/D ratio | 24 L/D |

(HDPE) Plasticizing capacity | 108kg/h |

Screw heating zone | 4 zone |

Screw heating power | 15.6kw |

Screw fan power | 0.14kw |

Extrusion motor power | 30kw |

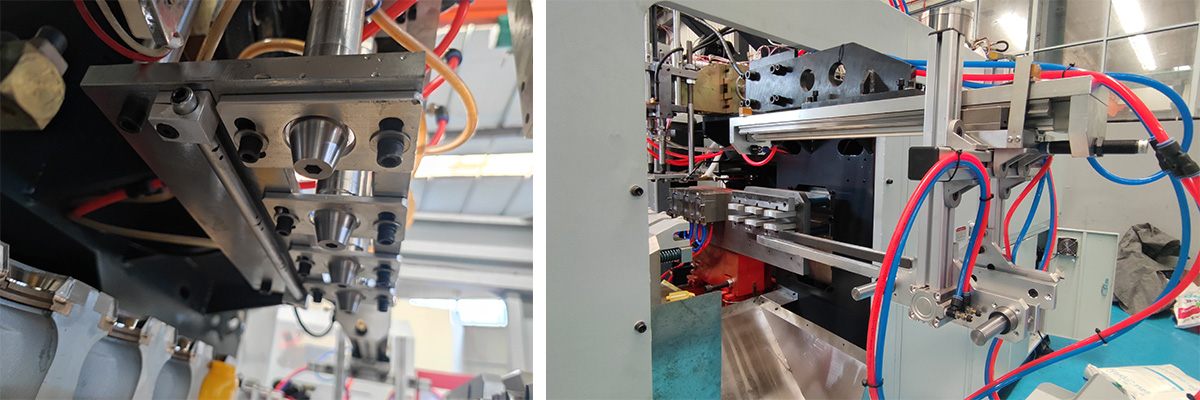

DIE HEAD |

|

Die head heating zone | 3 zone |

Power of die heating | 13.5kw |

ENERGY CONSUMPTION |

|

Total power of machine | 74.98kw |

Power of oil pump motor | 11kw |

Air pressure | 0.6-0.8 Mpa |

Average energy consumption | 35kw |

Consumption compression air | 1.5m3/min |

Consumption cooling water | 40L/min |

English

English