200L 220L 220 Litre Double L Ring HDPE Drum Making Extrusion Blow Molding Machine

| Layer: | |

|---|---|

| Availability: | |

| Quantity: | |

-

BSM120-220L

200L Blow Moulding Machine Description:

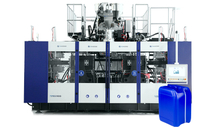

200L Blow Molding Machine for Double L Ring Drums is meticulously engineered to meet the exacting demands of industrial packaging, offering precision, reliability, and efficiency for the production of high-quality drums. With customizable options including 2 layers, 3 layers, or sin

gle layer configurations, it ensures versatility to match diverse production needs,high productivity 720 pcs per day.

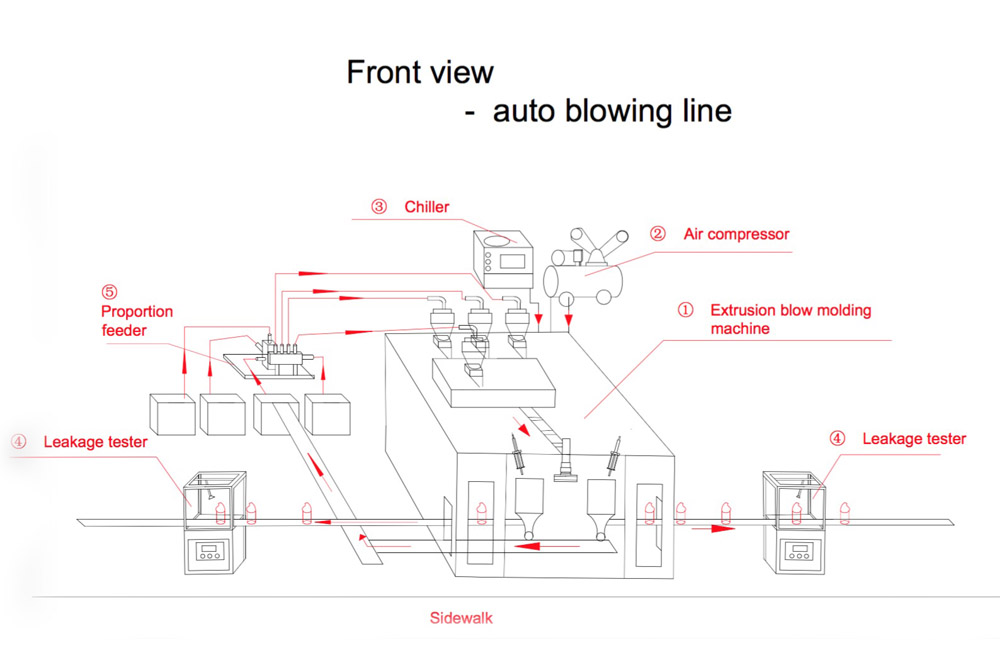

Fully automatic jerry cans blow moulding production line, including auto de-flashing, waste material and final bottles delivery, valid connection to other auxiliary equipment.

200L Blow Moulding Machine Technical Parameter:

| Specification | BSM120Z-220L |

| Max product volume (L) | 220L HMWHDPE |

| Machine weight (T) | 38 |

| Machine size(m) | 9.5X4.1X6.5 |

| Extrusion unit | |

| Screw diameter (mm) | 120 |

| Length/Diameter ratio | 30/1 |

| Heating zone No. (pcs) | 6 |

| Heating power (kw) | 47.4 |

| Cooling fan No. (pcs) | 5 |

| Fan power (kw) | 0.65 |

| Extrusion motor power (kw) | 132 |

| Plasticizing capacity (kg/h) | 320 |

| Die head | |

| Head type | accumulating |

| Accumulating volume (L) | 20 |

| Max ejection weight (kg) | 15 |

| Heating Zone No. (pcs) | 6 |

| Heating power (kw) | 38 |

| Max die diameter (mm) | 400 |

| Clamping unit | |

| Clamping force (KN) | 1500 |

| Platen size (mm) | 1200*1300 |

| Platen opening stroke (mm) | 800-1700 |

| Max mould size (mm) | 950*1600 |

| Mould thickness (mm) | 810-950 |

| Total power (kw) | 308 |

| Average energy consumption (kw) | 92 |

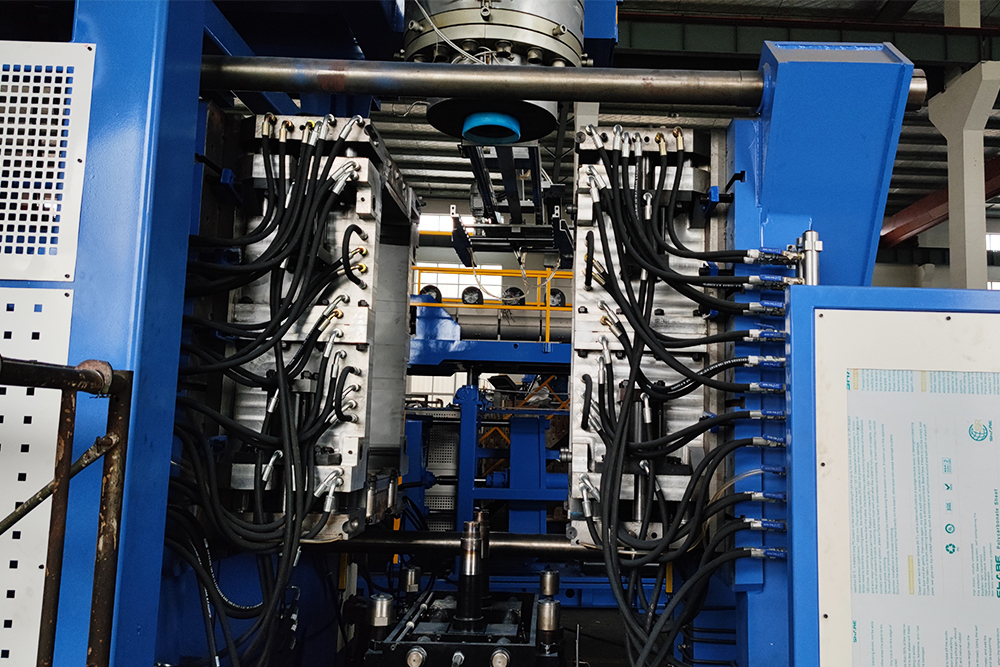

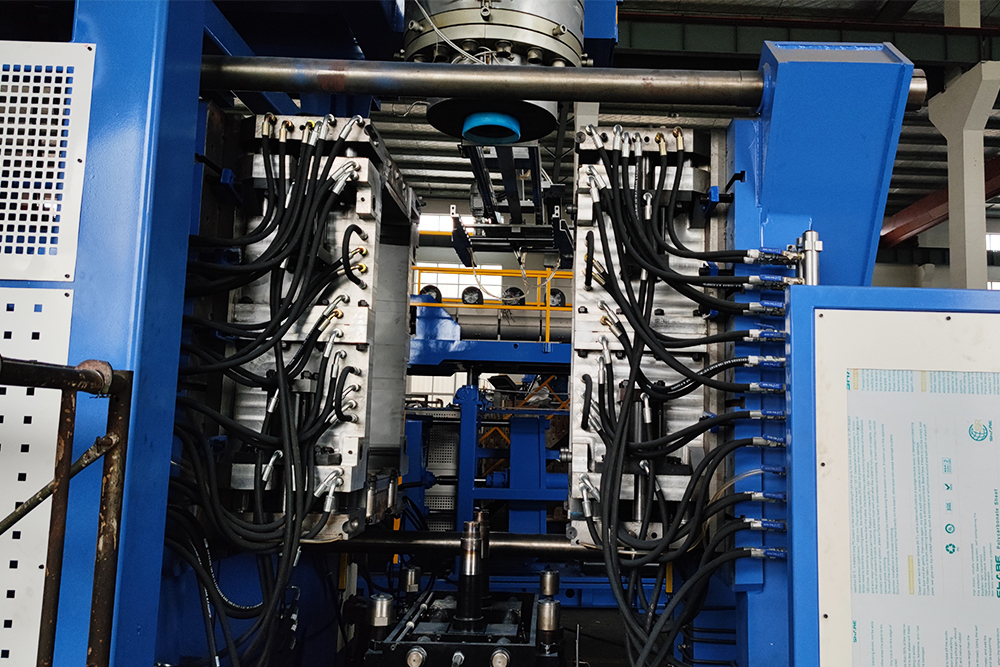

200L blow machine clamping system

200L Clamping System is a pivotal component in the production of industrial containers, ensuring the secure and precise sealing of 200-liter drums. Engineered with meticulous attention to detail, this system delivers unparalleled reliability and efficiency, meeting the stringent requirements of industrial packaging operations.

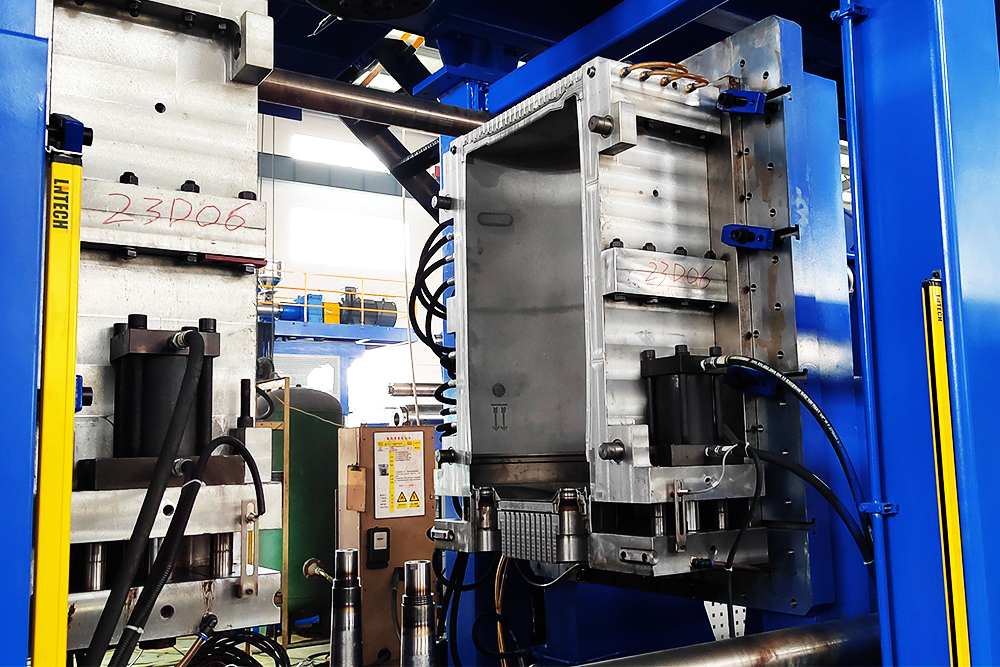

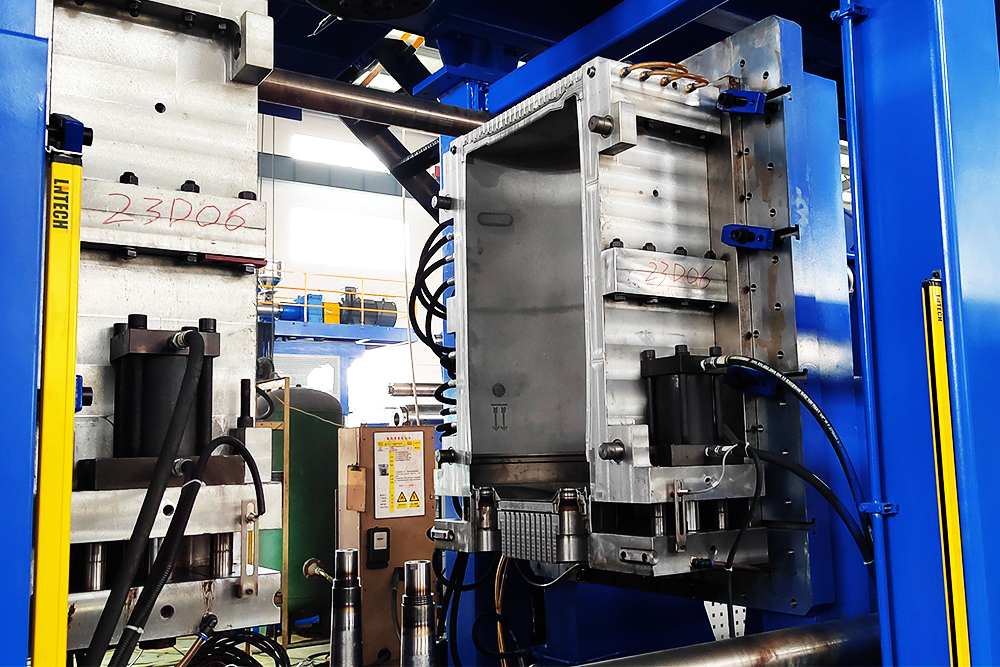

200L blow mold

200L Blow Mold: Precision-designed for uniform wall thickness and superior surface quality. Constructed with durable materials, suitable for chemical, food, and other industries, ensuring high-quality production of 200-liter industrial containers.

200L machine blow pin

200L blow pin facilitates efficient and precise inflation and molding of industrial containers. Featuring a dual needle system, it ensures simultaneous inflation and molding, enhancing production speed and consistency. Designed for reliability and performance, guaranteeing high-quality results and operational efficiency.

200L blow machine screw

200L screw line encompasses single, double, and triple screw options, catering to diverse industrial needs. Engineered for efficiency and sustainability, our screws enable material recycling to reduce costs and carbon emissions.

200L blow molding machine application

200L blow machine shipment

200L blow machine shipment

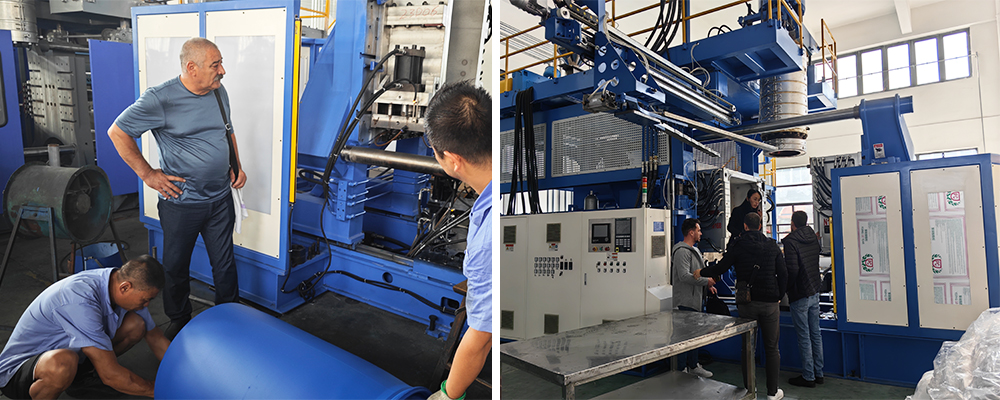

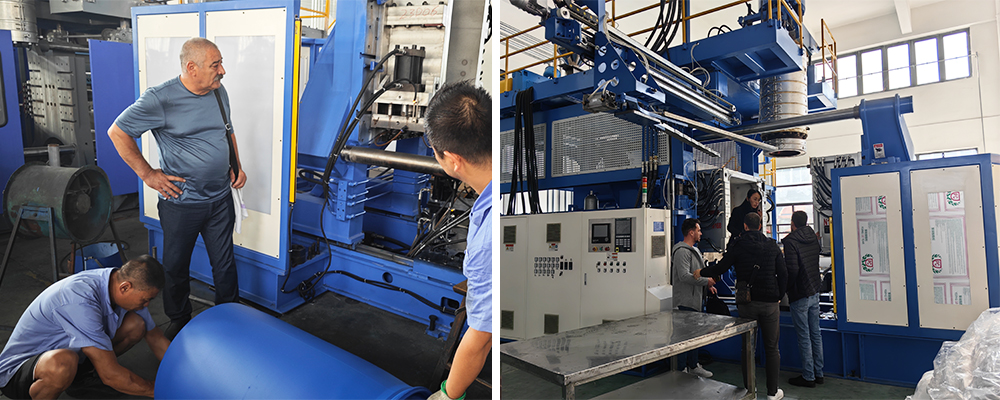

200L blow molding machine customer

200L Blow Moulding Machine Description:

200L Blow Molding Machine for Double L Ring Drums is meticulously engineered to meet the exacting demands of industrial packaging, offering precision, reliability, and efficiency for the production of high-quality drums. With customizable options including 2 layers, 3 layers, or sin

gle layer configurations, it ensures versatility to match diverse production needs,high productivity 720 pcs per day.

Fully automatic jerry cans blow moulding production line, including auto de-flashing, waste material and final bottles delivery, valid connection to other auxiliary equipment.

200L Blow Moulding Machine Technical Parameter:

| Specification | BSM120Z-220L |

| Max product volume (L) | 220L HMWHDPE |

| Machine weight (T) | 38 |

| Machine size(m) | 9.5X4.1X6.5 |

| Extrusion unit | |

| Screw diameter (mm) | 120 |

| Length/Diameter ratio | 30/1 |

| Heating zone No. (pcs) | 6 |

| Heating power (kw) | 47.4 |

| Cooling fan No. (pcs) | 5 |

| Fan power (kw) | 0.65 |

| Extrusion motor power (kw) | 132 |

| Plasticizing capacity (kg/h) | 320 |

| Die head | |

| Head type | accumulating |

| Accumulating volume (L) | 20 |

| Max ejection weight (kg) | 15 |

| Heating Zone No. (pcs) | 6 |

| Heating power (kw) | 38 |

| Max die diameter (mm) | 400 |

| Clamping unit | |

| Clamping force (KN) | 1500 |

| Platen size (mm) | 1200*1300 |

| Platen opening stroke (mm) | 800-1700 |

| Max mould size (mm) | 950*1600 |

| Mould thickness (mm) | 810-950 |

| Total power (kw) | 308 |

| Average energy consumption (kw) | 92 |

200L blow machine clamping system

200L Clamping System is a pivotal component in the production of industrial containers, ensuring the secure and precise sealing of 200-liter drums. Engineered with meticulous attention to detail, this system delivers unparalleled reliability and efficiency, meeting the stringent requirements of industrial packaging operations.

200L blow mold

200L Blow Mold: Precision-designed for uniform wall thickness and superior surface quality. Constructed with durable materials, suitable for chemical, food, and other industries, ensuring high-quality production of 200-liter industrial containers.

200L machine blow pin

200L blow pin facilitates efficient and precise inflation and molding of industrial containers. Featuring a dual needle system, it ensures simultaneous inflation and molding, enhancing production speed and consistency. Designed for reliability and performance, guaranteeing high-quality results and operational efficiency.

200L blow machine screw

200L screw line encompasses single, double, and triple screw options, catering to diverse industrial needs. Engineered for efficiency and sustainability, our screws enable material recycling to reduce costs and carbon emissions.

200L blow molding machine application

200L blow machine shipment

200L blow machine shipment

200L blow molding machine customer

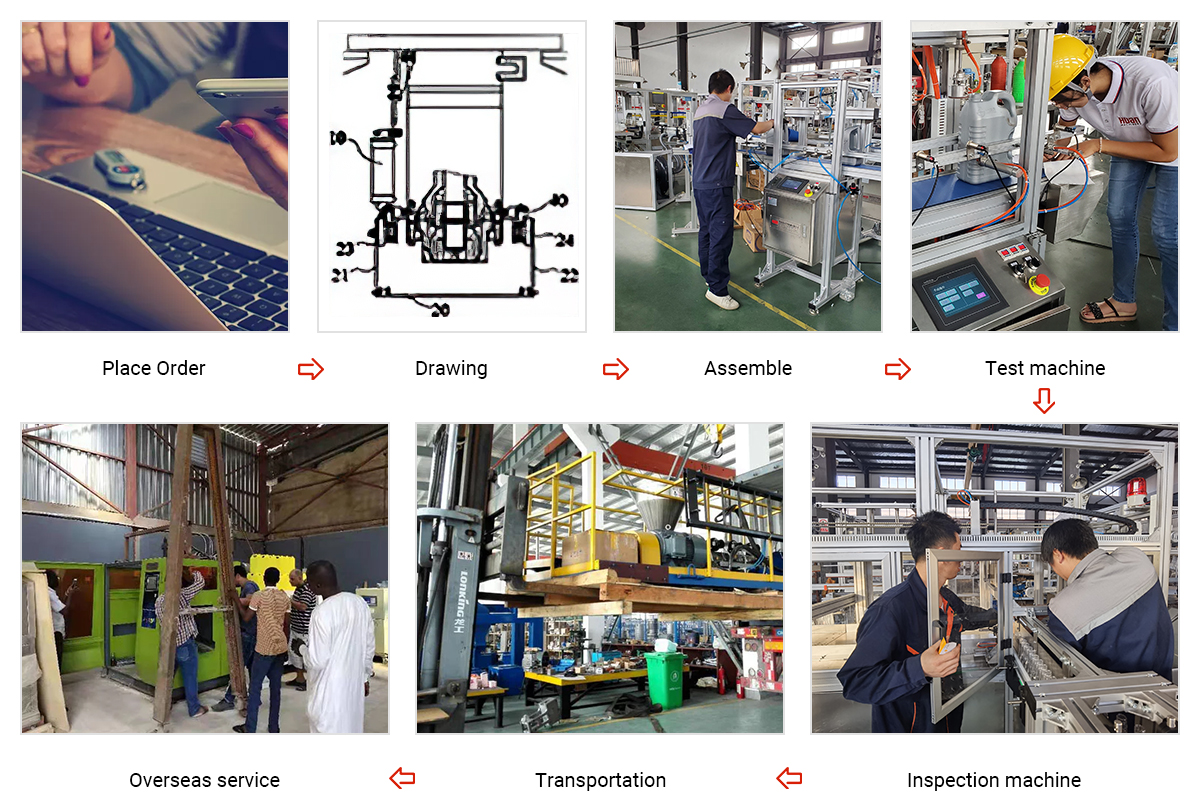

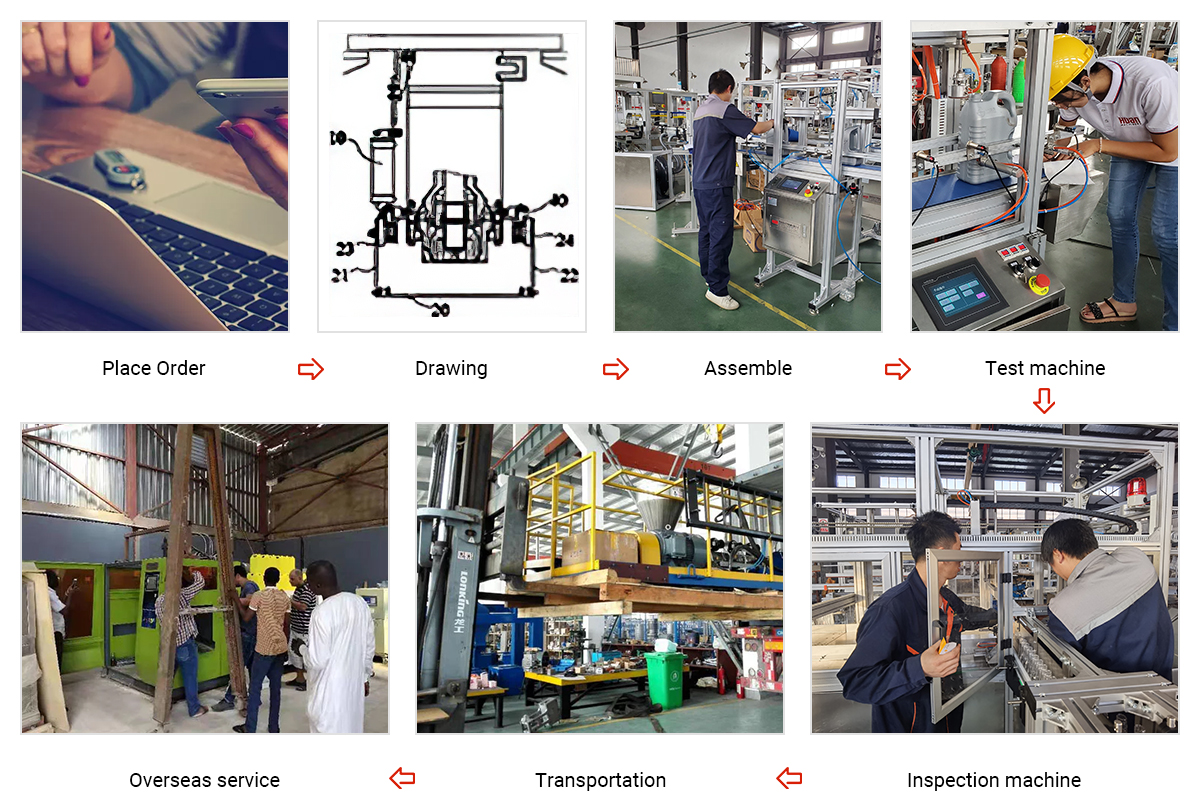

Choosing the suitable machine: We have a professional team, electrical engineers, mechanical engineers, commissioning engineers...Our engineers have been in this field over 18 years, have rich experiences. According to the customer’s plastic products and requirements , we could offer good solution based on experiences. And we also could recommend the related auxiliary machines to get a whole production line.

Customer’s visit: Before playing the order, warmly welcome to visit our workshop if customer interests. We will introduce our machines on site.

Delivery time: we will finish manufacturing and testing within delivery time, make sure customer’s production schedule. During the production process, we also will share the production progress photos and testing video with customer.

Warranty time: our warranty time is 12months after the delivery. During this period, any quality problem of the machine, we will send the replacement parts by express freely. If the buyer meet any technical problems, we will provide the support through remote control.

Training, installation: when the machine reaches the buyer’s factory, the buyer could tell us, we will dispatch an engineer to the buyer’s factory to help install and test the machine until it runs normally. Meanwhile, we also could help train the customer’s employee.

Choosing the suitable machine: We have a professional team, electrical engineers, mechanical engineers, commissioning engineers...Our engineers have been in this field over 18 years, have rich experiences. According to the customer’s plastic products and requirements , we could offer good solution based on experiences. And we also could recommend the related auxiliary machines to get a whole production line.

Customer’s visit: Before playing the order, warmly welcome to visit our workshop if customer interests. We will introduce our machines on site.

Delivery time: we will finish manufacturing and testing within delivery time, make sure customer’s production schedule. During the production process, we also will share the production progress photos and testing video with customer.

Warranty time: our warranty time is 12months after the delivery. During this period, any quality problem of the machine, we will send the replacement parts by express freely. If the buyer meet any technical problems, we will provide the support through remote control.

Training, installation: when the machine reaches the buyer’s factory, the buyer could tell us, we will dispatch an engineer to the buyer’s factory to help install and test the machine until it runs normally. Meanwhile, we also could help train the customer’s employee.