1 L 2 ltr 2.5 liter Rectangle hdpe container chemical liquid package bottle extrusion blow molding make machine

| Volume: | |

|---|---|

| Material: | |

| Layer: | |

| Availability: | |

| Quantity: | |

-

HSJ70D-3

-

HUAN

-

Chemical liquid bottle, jerry can, drum, ocean sea ball, water tank, food can, detergent liquid bottle

1 L 2 ltr 2.5 liter Rectangle hdpe container chemical liquid package bottle extrusion blow molding make machine

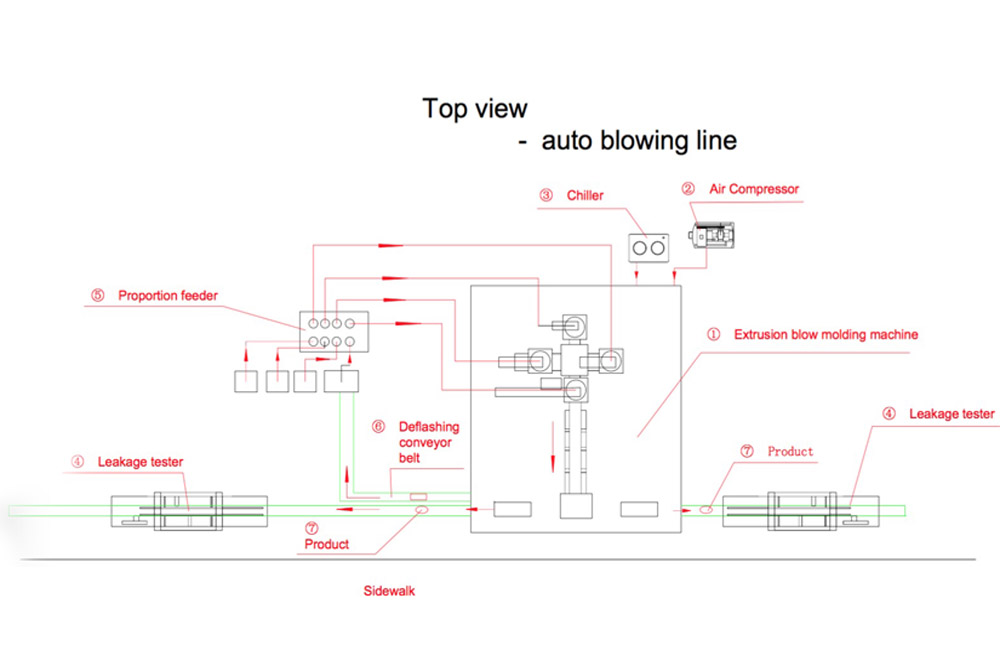

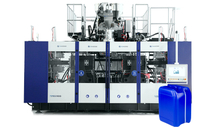

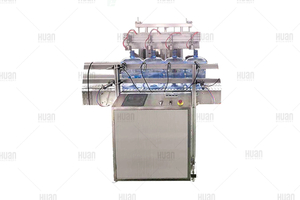

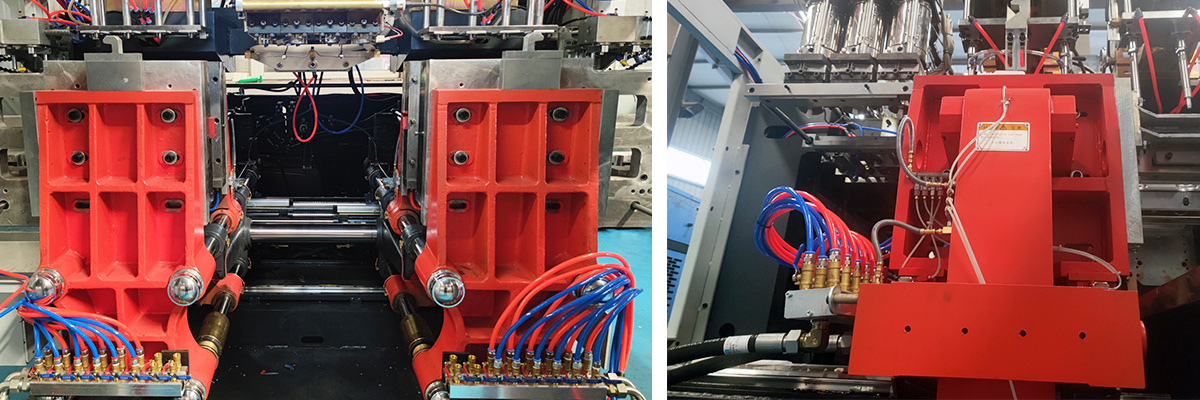

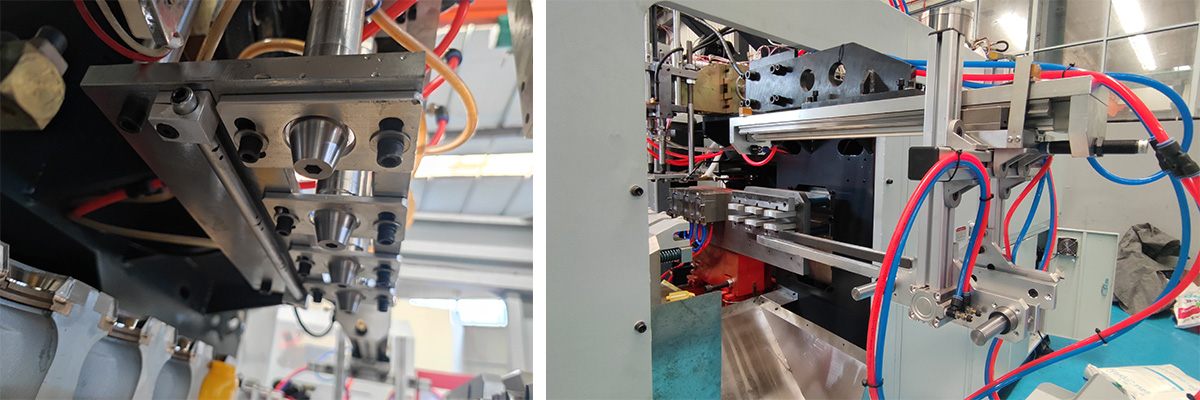

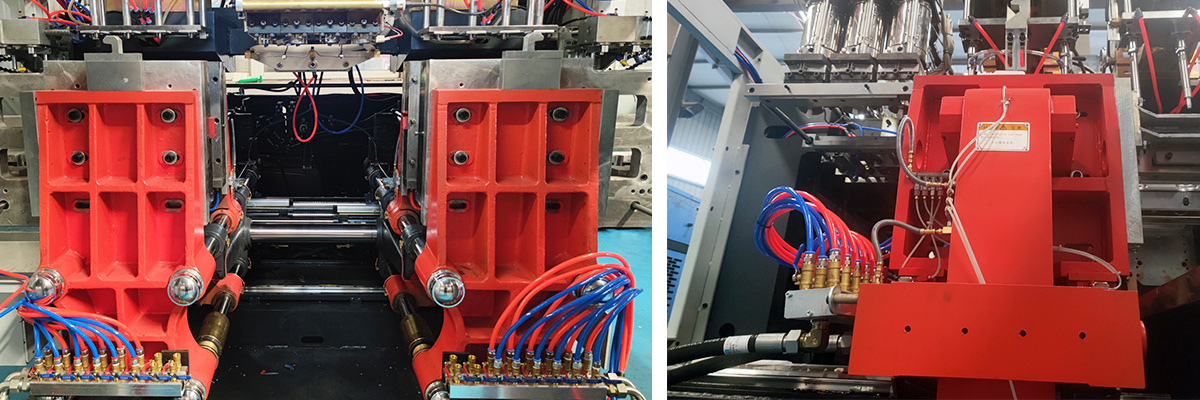

The extrusion blow molding machine is standard type machine with double station tie bar structure, The clamping structure is three or four tie bars direct locking structure with automatic lubrication system. The structure is simple and stable and it is convenient for plastics waste collection.

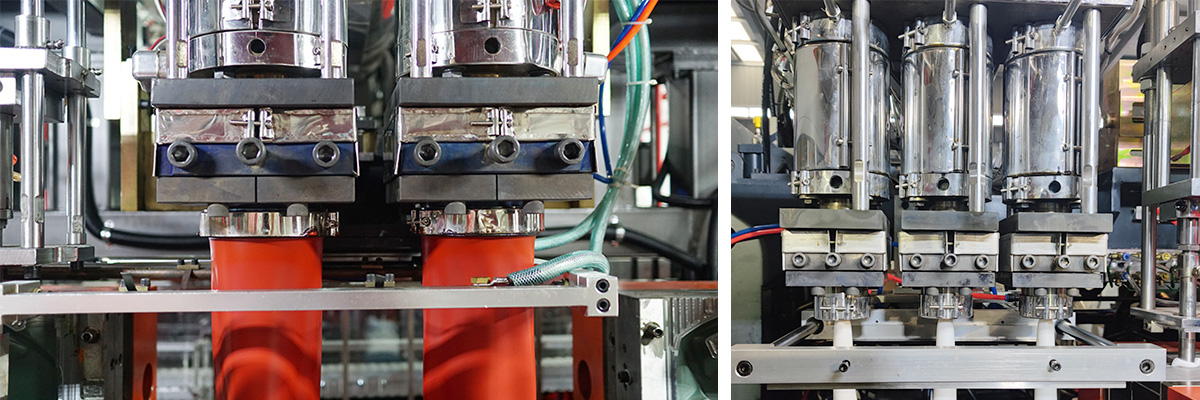

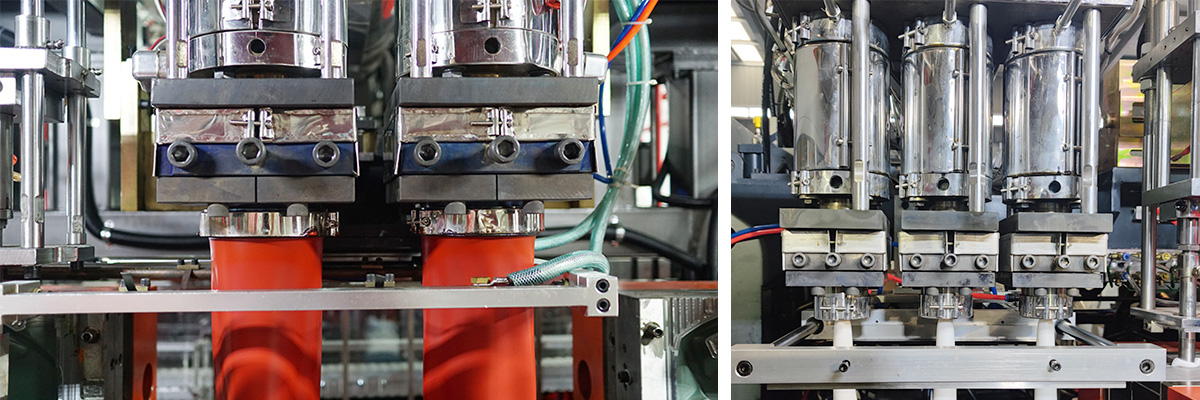

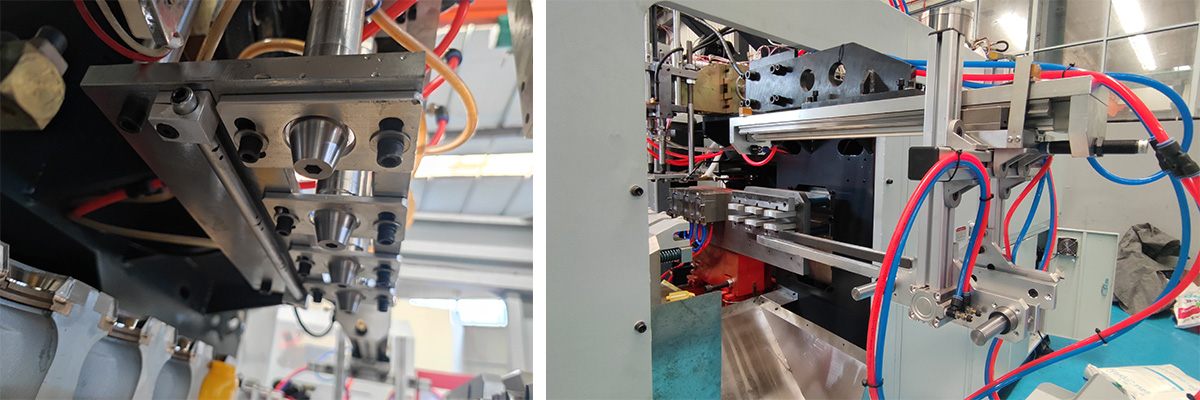

The whole machine adopts computer control, simple operation, reliable work, high degree of automation, good interchangeability of components,realize one machine multi-purpose. It can choose single and double mode-shifting models to meet different output requirements. It can be equipped with single head, double head, four head, multi-layer head, double transparent line head and servo wall thickness control head to meet the requirements of different products.The extrusion blow molding machine can produce multilayers hollow plastic products also,1 layer to 6 layer can be optional.

| SPECIFICATIONS | HJS70D/F |

| Material | PE PP PVC PA... |

| Max container capacity | 5L |

| Number of die | 123,4,6 |

| Machine Dimension(LxWxH) | 3.6x2.2x2.36m |

| Total weight | 5.5ton |

| CLAMPING UNIT | |

| Clamping force | 90kN |

| Platen openning stokes | 180-480mm |

| Carriage stroke | 450mm |

| Max mould size(WxH) | 430x470mm/430x400mm |

| EXTRUSION UNIT | |

| Screw diameter | 70mm |

| Screw L/D ratio | 24 L/D |

| (HDPE) Plasticizing capacity | 70kg/h |

| Screw heating zone | 3 zone |

| Screw heating power | 14.1kw |

| Screw fan power | 0.14kw |

| Extrusion motor power | 18.5kw |

| DIE HEAD | |

| Die head heating zone | 3 zone |

| Power of die heating | 6.5kw |

| ENERGY CONSUMPTION | |

| Total power of machine | 49.14kw |

| Power of oil pump motor | 9.5kw |

| Air pressure | 0.6-0.8 Mpa |

| Average energy consumption | 28kw |

| Consumption compression air | 1.2m3/min |

| Consumption cooling water | 40L/min |

1 L 2 ltr 2.5 liter Rectangle hdpe container chemical liquid package bottle extrusion blow molding make machine

The extrusion blow molding machine is standard type machine with double station tie bar structure, The clamping structure is three or four tie bars direct locking structure with automatic lubrication system. The structure is simple and stable and it is convenient for plastics waste collection.

The whole machine adopts computer control, simple operation, reliable work, high degree of automation, good interchangeability of components,realize one machine multi-purpose. It can choose single and double mode-shifting models to meet different output requirements. It can be equipped with single head, double head, four head, multi-layer head, double transparent line head and servo wall thickness control head to meet the requirements of different products.The extrusion blow molding machine can produce multilayers hollow plastic products also,1 layer to 6 layer can be optional.

| SPECIFICATIONS | HJS70D/F |

| Material | PE PP PVC PA... |

| Max container capacity | 5L |

| Number of die | 123,4,6 |

| Machine Dimension(LxWxH) | 3.6x2.2x2.36m |

| Total weight | 5.5ton |

| CLAMPING UNIT | |

| Clamping force | 90kN |

| Platen openning stokes | 180-480mm |

| Carriage stroke | 450mm |

| Max mould size(WxH) | 430x470mm/430x400mm |

| EXTRUSION UNIT | |

| Screw diameter | 70mm |

| Screw L/D ratio | 24 L/D |

| (HDPE) Plasticizing capacity | 70kg/h |

| Screw heating zone | 3 zone |

| Screw heating power | 14.1kw |

| Screw fan power | 0.14kw |

| Extrusion motor power | 18.5kw |

| DIE HEAD | |

| Die head heating zone | 3 zone |

| Power of die heating | 6.5kw |

| ENERGY CONSUMPTION | |

| Total power of machine | 49.14kw |

| Power of oil pump motor | 9.5kw |

| Air pressure | 0.6-0.8 Mpa |

| Average energy consumption | 28kw |

| Consumption compression air | 1.2m3/min |

| Consumption cooling water | 40L/min |

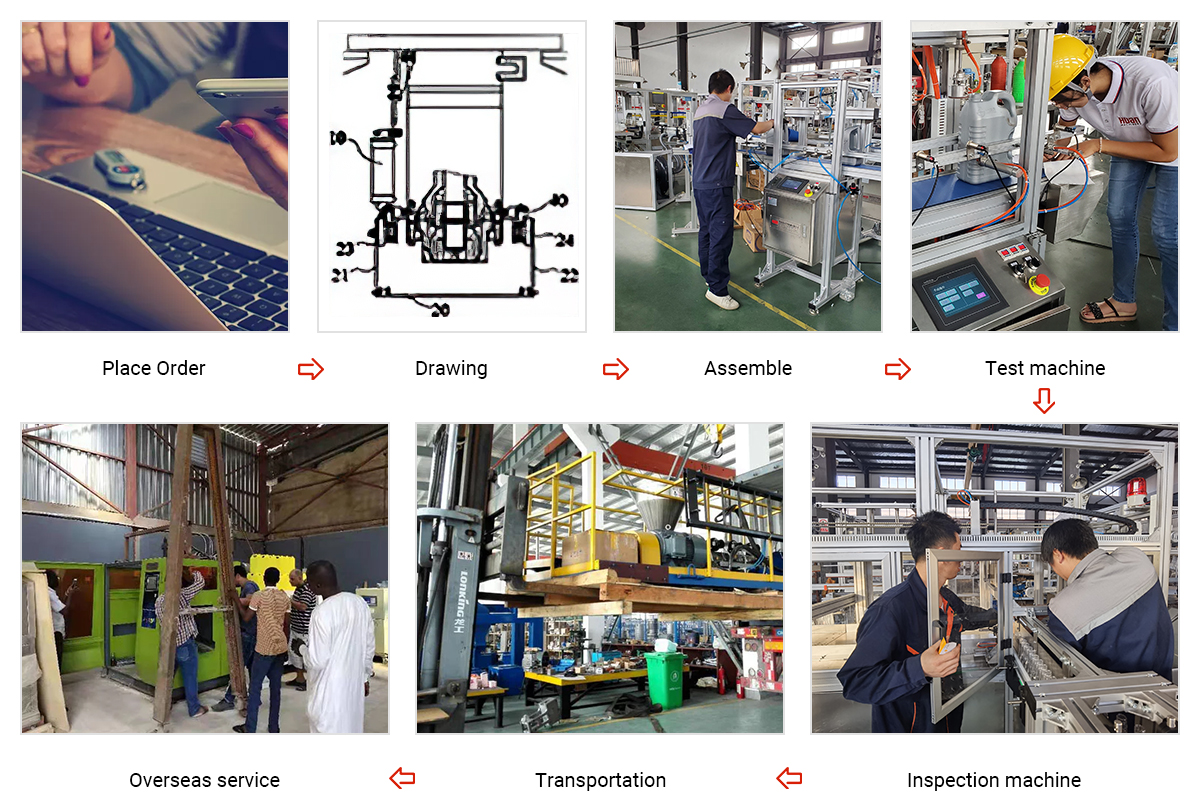

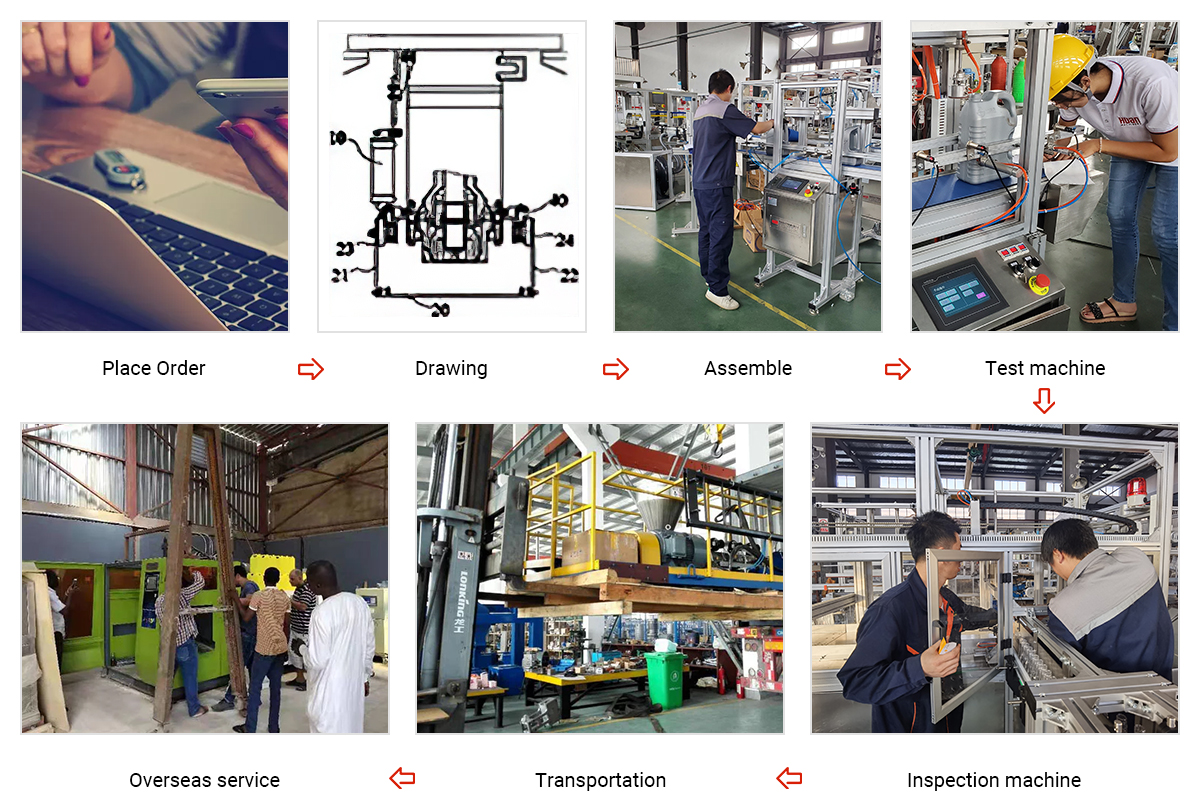

Choosing the suitable machine: We have a professional team, electrical engineers, mechanical engineers, commissioning engineers...Our engineers have been in this field over 18 years, have rich experiences. According to the customer’s plastic products and requirements , we could offer good solution based on experiences. And we also could recommend the related auxiliary machines to get a whole production line.

Customer’s visit: Before playing the order, warmly welcome to visit our workshop if customer interests. We will introduce our machines on site.

Delivery time: we will finish manufacturing and testing within delivery time, make sure customer’s production schedule. During the production process, we also will share the production progress photos and testing video with customer.

Warranty time: our warranty time is 12months after the delivery. During this period, any quality problem of the machine, we will send the replacement parts by express freely. If the buyer meet any technical problems, we will provide the support through remote control.

Training, installation: when the machine reaches the buyer’s factory, the buyer could tell us, we will dispatch an engineer to the buyer’s factory to help install and test the machine until it runs normally. Meanwhile, we also could help train the customer’s employee.

Choosing the suitable machine: We have a professional team, electrical engineers, mechanical engineers, commissioning engineers...Our engineers have been in this field over 18 years, have rich experiences. According to the customer’s plastic products and requirements , we could offer good solution based on experiences. And we also could recommend the related auxiliary machines to get a whole production line.

Customer’s visit: Before playing the order, warmly welcome to visit our workshop if customer interests. We will introduce our machines on site.

Delivery time: we will finish manufacturing and testing within delivery time, make sure customer’s production schedule. During the production process, we also will share the production progress photos and testing video with customer.

Warranty time: our warranty time is 12months after the delivery. During this period, any quality problem of the machine, we will send the replacement parts by express freely. If the buyer meet any technical problems, we will provide the support through remote control.

Training, installation: when the machine reaches the buyer’s factory, the buyer could tell us, we will dispatch an engineer to the buyer’s factory to help install and test the machine until it runs normally. Meanwhile, we also could help train the customer’s employee.

|  |

|  |  |  |

|  |

|  |  |  |

1. who are we?

We are based in Jiangsu, China, start from 2011,sell to Africa(00.00%),Western Europe(00.00%),North America(00.00%),South America(00.00%),Southeast Asia(00.00%),Mid East(00.00%),South Asia(00.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Extrusion Blow Molding Machine and Related Auxiliary Machines,Injection Molding Machine and Related Auxiliary Machines

4. why should you buy from us not from other suppliers?

More than 12 years manufacturing and exporting experience. We are a company with producing and exporting as well. We have clients to all over the world, accordingly we know each market well. My factory is near Shanghai airport with convenient traffic.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,Credit Card,Western Union,Cash;

Language Spoken:English,Chinese,Spanish

1. who are we?

We are based in Jiangsu, China, start from 2011,sell to Africa(00.00%),Western Europe(00.00%),North America(00.00%),South America(00.00%),Southeast Asia(00.00%),Mid East(00.00%),South Asia(00.00%). There are total about 5-10 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Extrusion Blow Molding Machine and Related Auxiliary Machines,Injection Molding Machine and Related Auxiliary Machines

4. why should you buy from us not from other suppliers?

More than 12 years manufacturing and exporting experience. We are a company with producing and exporting as well. We have clients to all over the world, accordingly we know each market well. My factory is near Shanghai airport with convenient traffic.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,EUR;

Accepted Payment Type: T/T,L/C,Credit Card,Western Union,Cash;

Language Spoken:English,Chinese,Spanish